Driving Innovation: How 3D Printing is Transforming Automotive Manufacturing

Production Time

70%

Reduction in lead times

Weight Reduction

35%

Lighter components

Design Freedom

100%

Complex geometries

The Manufacturing Challenge

The automotive industry has long faced significant challenges in balancing innovation with production efficiency. Traditional manufacturing methods often require extensive tooling, long lead times, and significant upfront investments, limiting the ability to rapidly iterate designs or create optimized components with complex geometries.

Key Industry Challenges

- •Long production lead times for specialized components

- •High costs associated with low-volume production runs

- •Limited design possibilities with traditional manufacturing

- •Difficulty maintaining inventory of legacy parts for older vehicles

3D Printing Solutions for Automotive

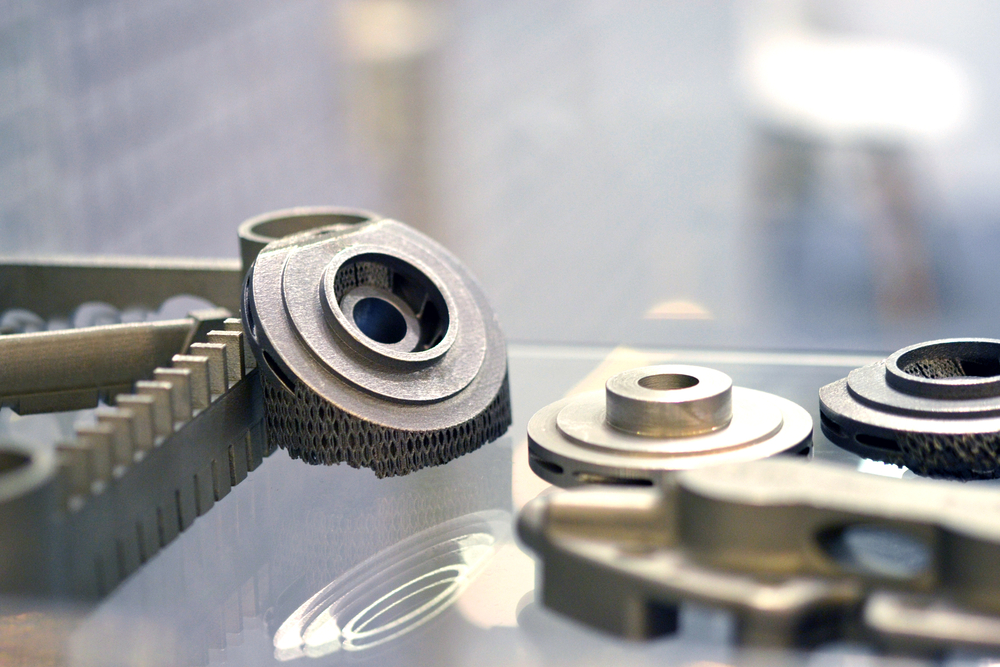

Additive manufacturing technologies are revolutionizing how automotive components are designed, prototyped, and produced. By enabling the creation of complex geometries impossible with traditional manufacturing methods, 3D printing is opening new possibilities for performance optimization, lightweighting, and customization.

Rapid Prototyping

3D printing enables automotive designers to quickly iterate through multiple design concepts, reducing the prototype development cycle from weeks to days, and significantly accelerating innovation.

Tooling & Fixtures

Custom jigs, fixtures, and assembly tools can be 3D printed at a fraction of the traditional cost, enabling more efficient manufacturing processes and shorter production lead times.

Transformative Results

Production Cost Reduction: For low to medium volume production runs, 3D printing can reduce manufacturing costs by up to 60% compared to traditional methods, eliminating the need for expensive tooling and minimizing material waste.

Lead Time Reduction: Automotive manufacturers can now produce complex parts on-demand in days rather than weeks, drastically reducing inventory costs and increasing supply chain resilience.

Design Optimization: Engineers can now create components with optimized geometries that improve performance while reducing weight, leading to improved fuel efficiency and vehicle performance.

"The integration of industrial 3D printing into our manufacturing process has been transformative. We've reduced our prototype development cycle by 70% while creating components with performance characteristics that would be impossible using traditional manufacturing methods."

— Michael Stern, Innovation Director, European Automotive Manufacturer

Applications Across the Industry

From prototyping to end-use parts, 3D printing is finding diverse applications throughout the automotive value chain. As the technology continues to advance, we're seeing increased adoption across multiple aspects of vehicle development and manufacturing.

Transform Your Automotive Manufacturing

Whether you're looking to optimize your prototyping process, solve supply chain challenges with on-demand manufacturing, or create high-performance components with optimized geometries, PRINTIV's advanced 3D printing services can help you:

- →Accelerate your product development cycle

- →Reduce costs for low to medium volume production

- →Create lighter, stronger, and more efficient components

- →Solve legacy part supply challenges